In a rare move, Toyota Motor Philippines Corporation (TMP) recently opened the gates to its sprawling 78-hectare, Philippine Export Zone Authority (PEZA)-accredited Santa Rosa, Laguna facility to guests and select members of the media. More specifically, the company allowed an even more exclusive look at its manufacturing operations – giving us permission to document the goings on via video and photography.

The star of the show was, of course, the Tamaraw – TMP’s comebacking commercial vehicle nameplate – just launched publicly last Friday and whose first units will arrive at showrooms early next year. Verily, the event was fittingly staged at the location where the TMP assembly lines churn out the Vios and Innova because the Tamaraw has joined these models as very proudly Philippine-made.

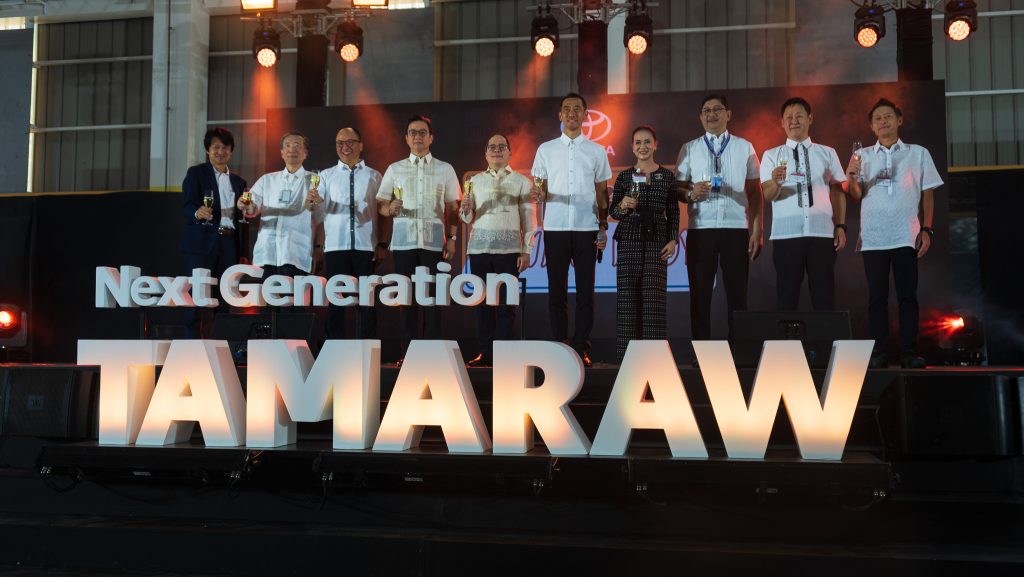

Appropriately, too, members of the TMP team comprised the bulk of the audience at the gym where the various iterations of the model were unveiled in a “roll-off” ceremony. “I have great confidence that the Tamaraw will be a resounding success in the Philippines, truly a game-changer, and will meet the evolving demands of our customers and strengthen further our footprint in this market,” said Toyota Asia Region Deputy CEO Hao Quoc Tien in his speech, personally addressing the TMP team, key stakeholders, government partners, and members of the media. He described the local assembly of the Tamaraw as “a capability breakthrough, being first of its kind in the Southeast Asian region.”

The iconic nameplate is truly back after a long sabbatical, and gets another run at embodying much of the company’s commercial/utility vehicle aspirations. Now based on Toyota’s new International Multi-purpose Vehicle 0 (IMV 0) platform designed for the Asian market, TMP Chairman Alfred V. Ty described the Tamaraw as a “super work vehicle” and “wonder vehicle.” He continued, “Just one year ago, we were honored by no other than President Marcos and Chairman Akio Toyoda to witness our CKD (completely knocked down) assembly lines, and today, we have all of you right here in Santa Rosa.”

Ty narrated that the Tamaraw, called an Asian utility vehicle when it was first introduced in December 1976, debuted in a high-side pickup (with roof) form, motivated by a 1.2-liter 3K engine mated to a four-speed manual transmission. Its second generation rolled out in the next decade, followed by the updated high-side pickup in 1991, and the third-generation Tamaraw FX Wagon in 1993.

The highly flexible Tamaraw is envisioned to provide “an inclusive mobility solution for micro, small, and medium enterprises (MSMEs) across various industries nationwide.”

Ty stressed that the Tamaraw is “built by Filipinos, for Filipinos,” and is “a testament to (TMP’s) commitment to nation building, our belief in Filipino craftsmanship, and our continuing mission to create ever-better cars for the Philippines.”

In a release, TMP maintained that the Santa Rosa factory boasts a “capacity exceeding 54,800 units annually,” With the addition of the Tamaraw to its CKD roster, “(the) expansion aims to bolster local capabilities and regional competitiveness, drive technology transfer, and sustain employment.”

As mentioned, we were invited for a brief tour of the so-called TMP Conversion Factory – measuring 1.5 hectares and completed at a cost of P1.1 billion. This ups the total investment in the IMV 0 project to a cool P5.5 billion, spent on “earlier investments in vehicle production, in-house and outsourced parts localizations.” The factory rolls out the Tamaraw in three body styles – dropside, utility van, and aluminum van forms – available in gas or diesel powertrains.

Meanwhile, speaking with reporters after the unveiling, TMP President Masando Hashimoto explained, “This commercial vehicle area is very new to Toyota. After 2004, we stopped the commercial vehicle line (of the Tamaraw). This market is (now) dominated by Mitsubishi and Hyundai and we are quite behind. We are now the challenger… It’s a new model, but for all employees of TMP, it represents a new program for us to train ourselves – for production and marketing – because everything is new. This (should be) a good experience for all Toyota employees.”

He reiterated, “We need to develop again the image of Toyota in this specific category. In passenger cars, we have no problem, we are very confident. But in this (utility vehicle space) is really a big challenge.”

The executive said he expects the “utility vehicle” guise of the Tamaraw, among its many iterations, to gain the most traction in the market. This used to be called the FX, and it was renamed, insisted Hashimoto, to “avoid confusion.” The confidence in the variant is predicated on its versatility. “It is our focus model.”

Production rollout, per the executive, should total “around 20,000” units a year, with a monthly output of 1,500 to 1,800 – the latter figures also reflecting the expected sales volume across TMP’s nationwide dealership network.